Pearl wave

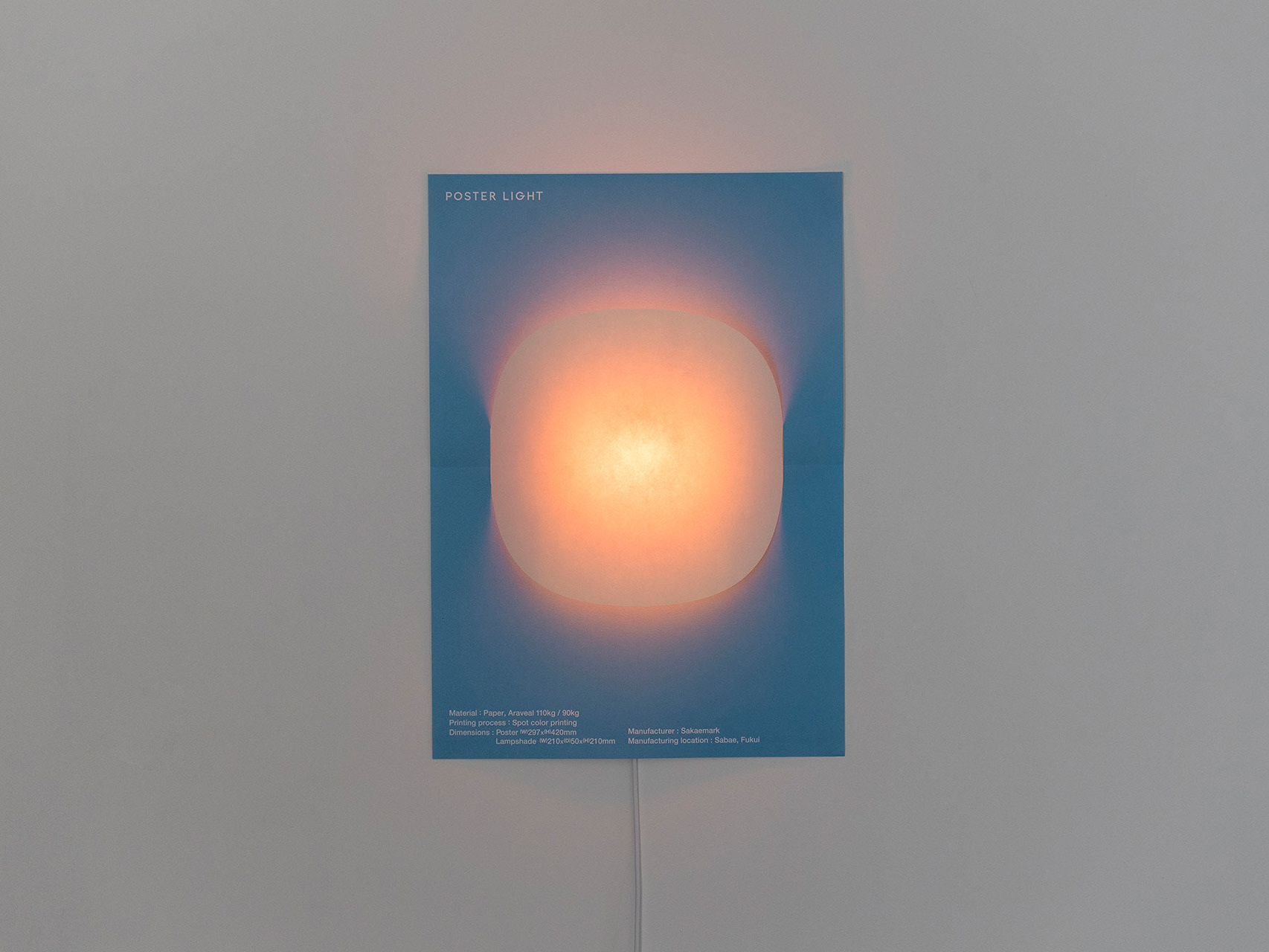

REMAREの素材は廃プラスチックを再利用し、熱プレスによって板状に成形された後、NC加工機によって表面が滑らかに仕上げられ板状の製品となります。本シリーズ「Pearl Wave」では、この工程をあえて手作業で仕上げることで、素材の質感をより引き出すことに挑戦しています。表面には、日本の伝統的な技法である「なぐり加工」を施し、刃物による不規則な凹凸をつけることで、波のような有機的な模様が浮かび上がります。この造形により、素材のもつ半透明性や光の透過の美しさが際立ち、“shinju”の質感を一層引き立てます。また、傷やネジ穴埋めを目立たなくさせ、滑り止めにもなるという機能性も持ち合わせています。さらに、REMARE素材の熱可塑性を活かし、曲面同士を組み合わせた構造や、光を内包する照明としての展開など、機能と表情の両面から、素材固有の魅力を引き出すデザインを試みています。 REMARE is made from recycled waste plastic, and after being formed into a board shape by a heat press, the surface is smoothed and finished by an NC machine to become a board-shaped product.In the "Pearl Wave" series, this process is done by hand to bring out the texture of the material.The surface of the product is finished with the traditional Japanese technique of "Naguri-work," in which a blade is used to create irregularities, resulting in an organic pattern that resembles waves.This process accentuates the translucency of the material and the beauty of light transmission, further enhancing the texture of "shinju".It also has the functionality of making scratches and screw holes less noticeable and preventing slipping.Furthermore, taking advantage of the thermoplasticity of the REMARE material, we have attempted to create a design that draws out the inherent appeal of the material in terms of both function and expression, such as a structure that combines curved surfaces and a development that uses the material as a lighting source that contains light.